Designed to be unstoppable

The machine created to cut and chamfer tubes and bars

See what’s possible

BC80 General information

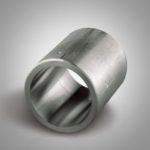

Continuous, certified bushing production

Non-stop production 24 hours a day of bushings up to 80 mm (3.125”) diameter of length 80 mm and from 10 to 350 mm (.4” to 13.75”) long. BC80 is the fully automated solution for sawing, chamfering and measuring parts made from tubes and solid bars.

Easy to use and maintain

Performing routine maintenance operations (e.g. tool and saw blade change) is easy with the large access doors on both sides of the machine.

Reliable process, maintains profit margin

The measuring stations are located in the upper portion of the work area to prevent interference from chips and debris.

Dynamic part washing flushes the part prior to measurement.

Process reliability is assured.

Produce up to 2,200 parts/hour

The BC80 was designed for one task and it performs it perfectly.

That’s why it is the best performing bushing maker available on the market.

Programming: straight to the goal

The programming guides you to input part and chamfer dimensions, material info, and holder dimensions. From there the machine automatically applies the perfect cutting conditions to maximize productivity.

Anything is feasible

Are your parts more complex?

With the EM80 you can make chamfers plus you can also turn, thread, knurl, tap, drill and mill radially.