When deciding to invest in a laser cutting system, the first thing to consider is – of course – the most obvious, that is the machine, its technical features and its constructive solutions to seek maximum robustness and reliability.

Only later does the thought go to the programming tools. However, it is important to consider that the latter is what you will be working with on every day and make the difference between efficiency and inefficiency.

So, looking into the “control centre” in detail is very important. The programming and production planning environment must be easy to use and powerful enough to exploit every function of the machine.

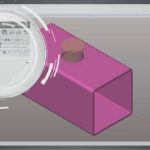

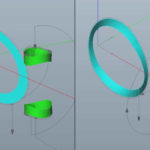

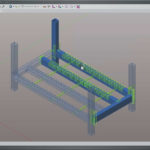

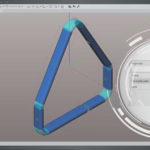

This is Artube 3: an all-graphic 3D CAD/CAM program dedicated specifically to designing tube components. It:

guides you to choose the right technical solutions according to the job

shows you only the applicable operations in all steps

transforms the drawings of single parts and entire frames into perfectly optimised programs for the machines in a few clicks

interfaces easily with other CAD programs to import 3D models in the most common formats

allows to apply adjustments until the end without needing to edit the source drawing.

Artube 3 means getting off to a good start in the world of tube laser cutting. This successful processing method counts thousands of happy customers worldwide and today with the third generation is the most powerful solution available on the market. Ask for a demonstration and compare the tools you will be using every day and which will impact your return on investment