Programming and 3D simulation software of part program allows:

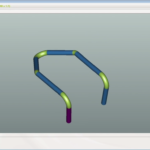

by simply inputting the components bend coordinates, the complete bending program is graphically simulated;

pre-production calculation of the real cycle time is known, so production costs and component pricing can be more precise;

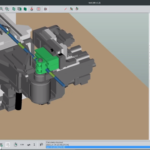

component feasibility can be checked without physically testing on the machine or making prototype tooling;

quick feedback to customers;

likely collision risks are highlighted and the most efficient avoidance route selected automatically;

working cycle generated by the VGP3D.

Integrated piercing program

Management of the main profiles (round, square, rectangular, oval, elliptic and semi-oval)

Intuitive program modification (no special know-how such as ISO programming is needed) by means of the touch screen, i.e. touching and dragging components (drag & drop)